On the afternoon of June 12, Saint-Gobain Research (Shanghai) Co., Ltd. was recognized as one of the China National Technology Trade Innovation Practice Cases at the 10th China (Shanghai) International Technology Import and Export Fair, along with other 24 companies.

The theme of Saint-Gobain's case is "Deeply Cultivating Green Grinding Technology Development to Support Low-Carbon Development of Advanced Manufacturing". The case involves four new products developed by the Shanghai R&D team, which collectively facilitate the evolution of grinding technology in China's steel, high-speed rail, and electric vehicle industries.

Led by Zehua Shi, the MILLINIUMTM Second Generation Roll Grinding Wheel was developed with significantly enhanced performance and increased wheel life by 40%. Carbon emissions are reduced by 24% during production and use. The increased wheel life reduces solid waste generation per unit output by 29%, resulting in improved environmental impact . This technology has received invention patents in China, Japan, and South Korea and has applied for PCT (The International Patent System) in the United States, India, Europe, and other regions. The Shanghai R&D team has exported the new roll grinding product technology to four Saint-Gobain plants located in the United States, Germany, India, and Brazil, embodying the concept of Chinese innovation serving the world and contributing to global steel industry’s decarbonization.

Also led by Zehua Shi, the high-speed rail track grinding wheel achieves grinding operations at 75 km per hour, replacing imported German wheels. This not only reduces production costs and shortens delivery time, but also enhances China's high-speed rail track maintenance capabilities. Moreover, it has a significant market share advantage in China's high-speed track grinding market, contributing to sustainable and efficient travel in China.

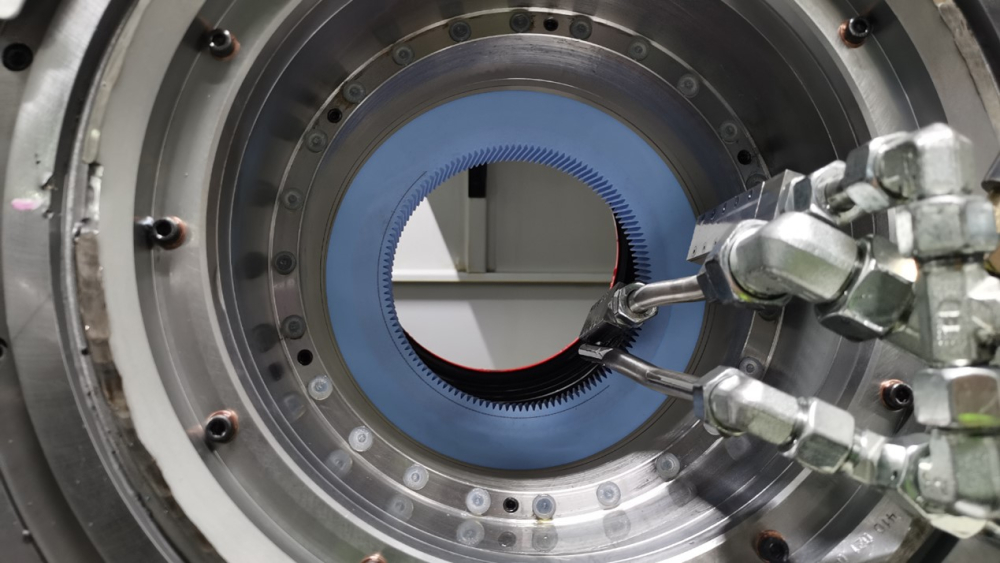

Developed by Colin Zhang and Luke Luo, the XTRIMIUMTM worm grinding wheel is designed for gear processing in electric vehicles. It has become the market leader in grinding efficiency, gear surface quality (after grinding), and wheel performance stability. It was awarded the Ringier Technology Innovation Award for Manufacturing in August 2020. Two invention patents for this product have been applied for PCT in the United States, Germany, and other countries. Meanwhile, the Shanghai R&D team has exported the new worm grinding product technology to Saint-Gobain Abrasives plants located in the United States, Germany, and Poland.

Developed by Jessie Wang, Luke Luo, and Colin Zhang, the gear power honing wheel is mainly used for gear processing in electric vehicles. It reduces vehicle noise, energy consumption in the transmission system, and extends gearbox life. This innovative technology has been successfully implemented by clients like BYD and Geely, shortening development cycles of new gear honing. It is also the first wheel in the market to achieve multiple groove capabilities, extend honing wheel life, reduce production costs, and cut fixed waste by over 50%, contributing to environmental protection.

This award, selected by the Ministry of Commerce of China from numerous outstanding cases nationwide, went through multiple review by different levels of business commission officials and was finally decided by external expert evalsuation. It signifies the Chinese government's recognition of Saint-Gobain's efforts in green manufacturing and energy conservation, encouraging the Abrasives R&D team to continue developing more advanced and innovative products and contributing to sustainable manufacturing practices.